Industrial heat pumps

HEAT PUMPS FOR LARGE-SCALE APPLICATIONS - FOR HEAT SOURCES WATER / BRINE / AIR

» Heat pumps for large capacities up to 2,000 kW

» For large commercial, industrial, and municipal facilities

» Heating, active cooling, and domestic hot water preparation

» Supply temperature up to 130°C

» OVi technology ensuring highest efficiency

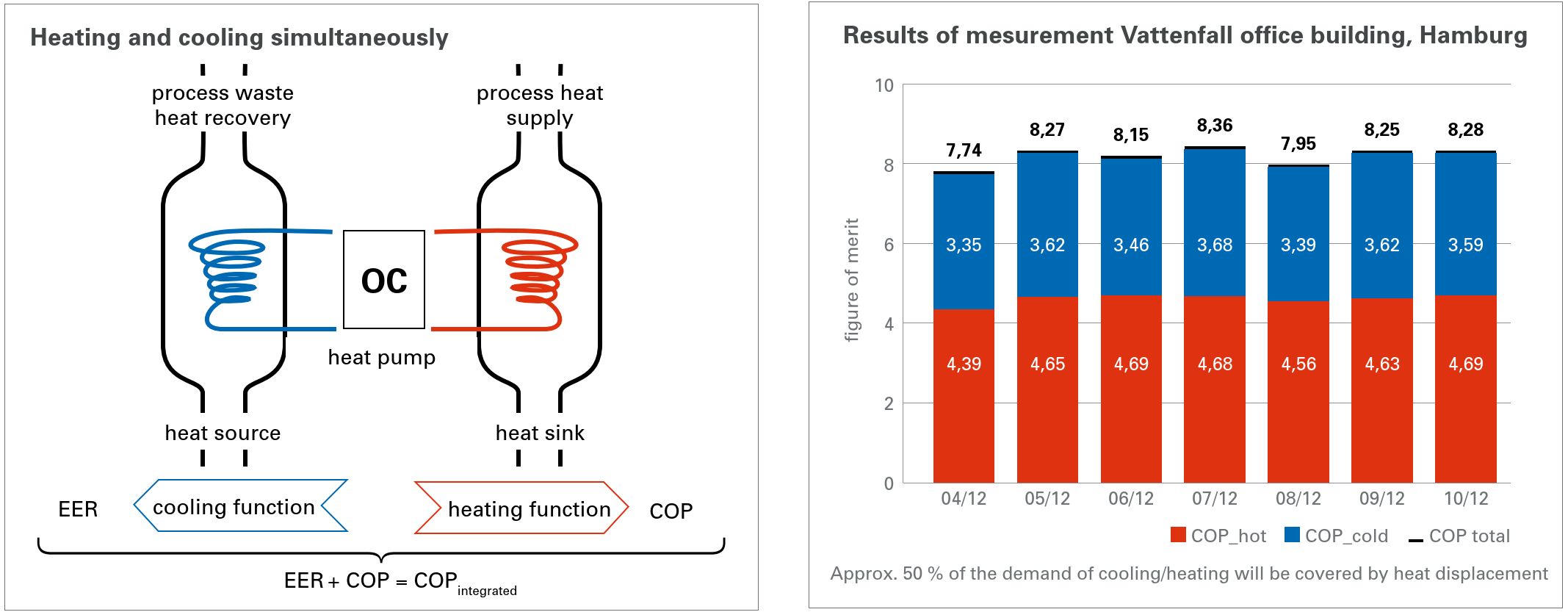

SIMULTANEOUS HEATING AND COOLING IN BUILDINGS AND PROCESSES

BUILDINGS

Both heating and cooling loads are often present in many buildings simultaneously. Instead of generating heat using a fossil fuel furnace and simultaneously cooling using a water chiller, a heat pump can simultaneously fulfill both functions (heating and cooling).

TECHNOLOGICAL PROCESSES

Exhaust heat is largely unused and pollutes the environment. In many processes, heating and cooling are generated separately. Heat recovery through heat exchangers reaches its limits. By simultaneously using the cooling and heating functions of heat pumps, heating coefficient of performance (COP) and cooling energy efficiency ratio (EER) can be summed up (heating COP + cooling EER = integrated COP). This achieves phenomenal energy efficiency and cost savings. Energy efficiency guideline requirements are met by saving primary energy, and CO2 certificates can be awarded for CO2 emission reduction.

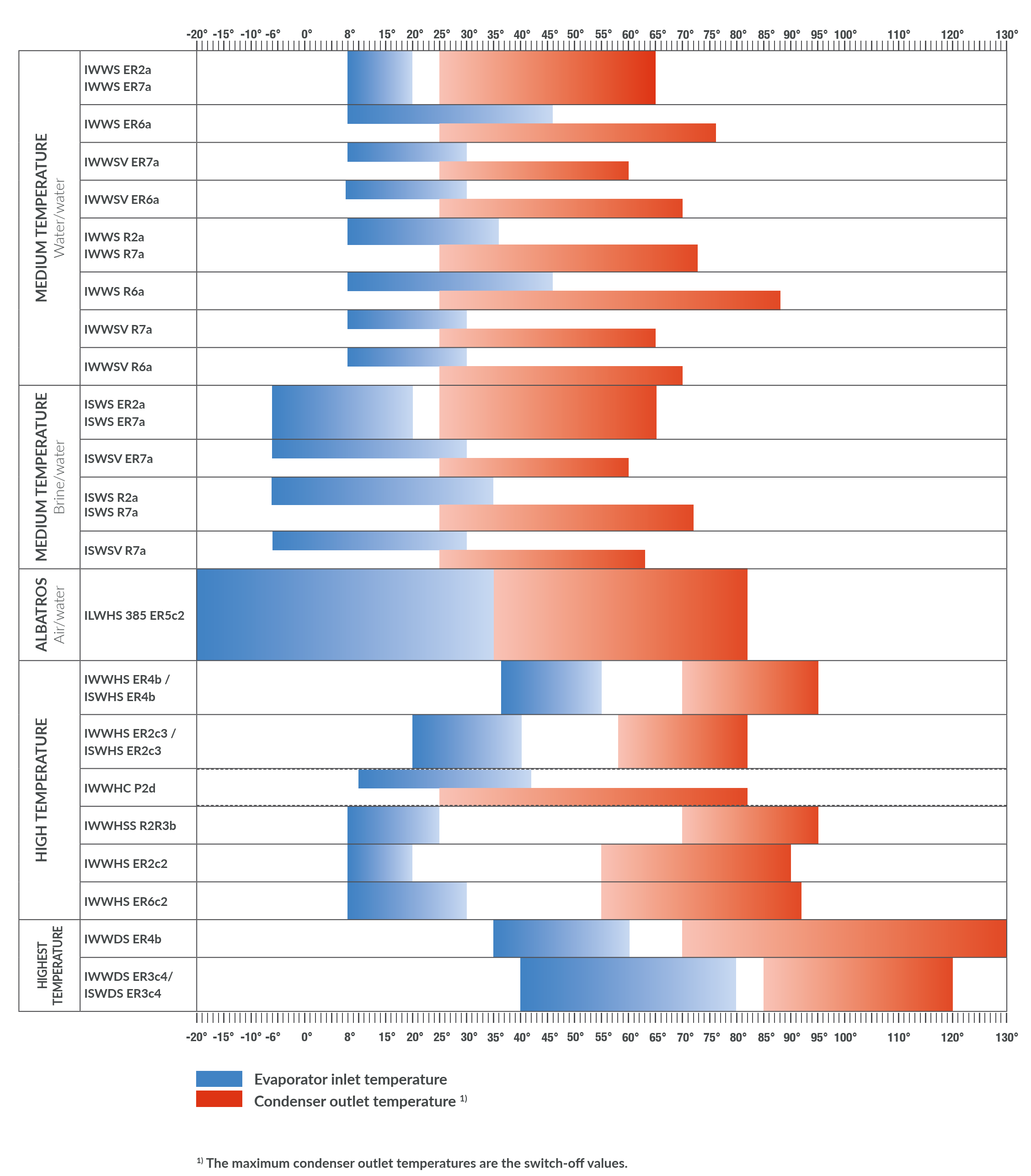

Industrial Heat Pump Series and Temperature Range

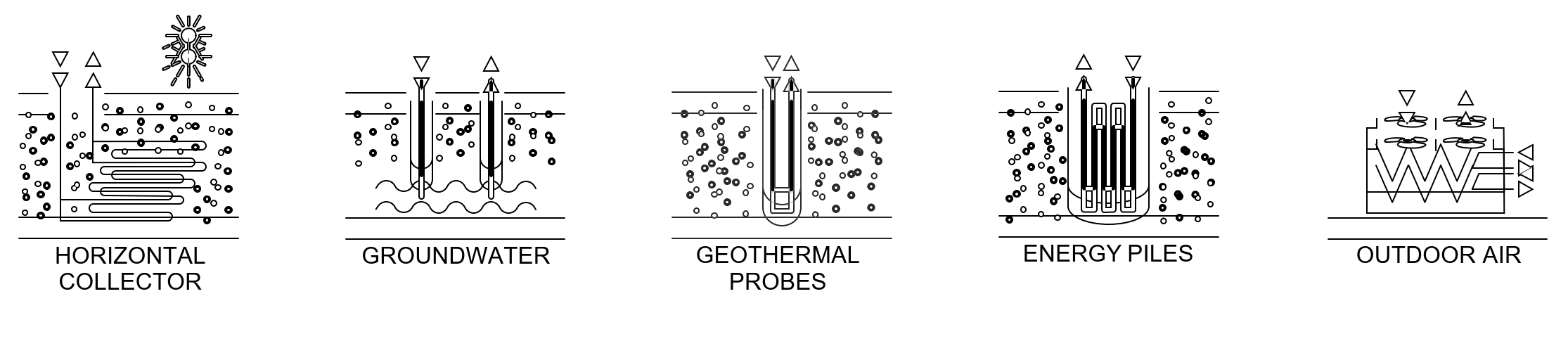

UTILIZATION OF RENEWABLE ENERGY

Renewable energy derived from ambient heat ensures cost-effective, efficient, and risk-free energy supply in the long term. To heat and cool buildings as efficiently and economically as possible, the ideal solution is next-generation heat pumps.

RENEWABLE HEAT SOURCE - ENVIRONMENTAL HEAT

- Groundwater

- Soil

- Cold geothermal

- Waste heat

- Outdoor air

HIGH-RISE BUILDINGS

Heating and air conditioning of office buildings, residential buildings, administrative buildings, educational institutions, hospitals, supermarkets, warehouses, manufacturing plants, etc.

RESTAURANTS AND SPORTS FACILITIES

Room heating, pool heating, hot water preparation, air conditioning

AGRICULTURE

Greenhouse heating or heating of fish ponds.

INFRASTRUCTURE

Maintenance of roads, railway systems, concrete slopes, grass, and sports fields in ice-free conditions

ENERGY EFFICIENCY

Using heat pumps, previously unused streams of waste heat - which would otherwise be lost - can be converted into usable heat. With this kind of energy recycling, thermal losses are avoided, and the overall system efficiency/energy balance is reconsidered. The heat source and the heat pump radiator operate simultaneously - this halves energy costs.

WASTE HEAT SOURCE:

- Waste heat from server rooms/data centers

- Waste heat from air conditioning systems/refrigeration networks

- Heat from exhaust gases

- Urban sewers and wastewater treatment plants

EXAMPLES OF INDUSTRIAL HEAT PUMP APPLICATIONS:

- Heating and cooling in chemical processes

- Heating and cooling in the food industry

- Heating and cooling in the beverage industry

- Heat recovery from refrigeration systems

- Heat recovery from exhaust gases in heat plants

- Heat recovery from cooling water in power plants

- Heat recovery in the plastics industry

- Heat recovery from mechanical processes

- Expansion of district heating networks through the use of return flow as a heat source

COLD DISTRICT HEATING NETWORKS: HEATING AND COOLING BECOMES A REALITY

Due to the low temperatures in the network, the difference compared to ground temperature is also small. This means that there is no need to use often costly insulation of pipes in the network, as ideally, the network absorbs heat directly from the surroundings. This means that there are minimal or no losses in the network pipes. However, due to the small temperature difference between supply and return and the generally low temperature level, large flows are required. This means larger pipelines and greater demand for pump power, so cold district heating networks can incur higher costs in this regard. Basically, in the case of these networks, reverse operation for building cooling is also possible. This will become increasingly important as temperatures rise in the future; even in Poland.

To supply houses via energy networks, they must have a decentralized heat pump because the operating temperatures are not sufficient for hot water production and heating. The heat pump raises the temperature to the required level. Cooling production works in the same way. Additionally, the waste heat generated in this process can be reintroduced into the heating network. This means that users are not only customers but can also act as prosumers. Depending on the circumstances, they can consume or generate heat or cold.

The Importance of Cold District Heating Networks for Energy Transformation

Utilizing local cold heat or local or district cooling has tremendous potential for the success of thermal and hence energy transformation. This is because many different resource-saving sources can be used to produce this type of heat or cold. For example, all forms of renewable energy can be utilized, as well as waste heat from industry or heat from the ground or bodies of water. This type of supply is therefore an interesting element of a successful transition to a CO2-free heating system.

INDUSTRIAL HEAT PUMPS

COLD DISTRICT HEATING NETWORKS - MEDIUM-TEMPERATURE SERIES with scroll compressors

working fluid temperature 65°C

APPLICATION AREAS

- Heating, cooling, domestic hot water preparation

- Single-family houses, solution for cold local heating networks

- Floor-by-floor solution in residential buildings - new construction and renovation

- Heat source: cold district heating networks brine from -10°C to +20°C

CONSTRUCTION

- Compact brine heat pump

- Integrated domestic hot water tank

OUTPUT RANGE

Variable heating power from 1.5 - 7.1 kW with a 180-liter stainless steel hot water tank

ISWS, IWWS SERIES MEDIUM-TEMPERATURE 75 - POWER RANGE 110 kW to 1.1 MW, TWIN-UNIT up to 2.2 MW

with screw compressor - working fluid temperature 75°C

APPLICATION AREAS

- Heating and cooling

- Large-volume buildings such as office buildings, hospitals, production halls

- Heat source: geothermal energy, groundwater, waste heat from sewage, refrigeration systems, computer centers, etc.

CONSTRUCTION

- Durable, high-efficiency compact screw compressors

- Stepwise, stepless, or inverter capacity control

- Robust shell-and-tube heat exchangers as evaporator and condenser for maximum durability and reliability

CAPACITY RANGE

Heating power from 110 kW to 1.1 MW, as TWIN unit up to 2.2 MW

COMPRESSOR

- Semi-hermetic compact screw compressor

- Shaft rotation on asymmetrical high-quality profiles

- Slide valve control 50%, 75%, 100%, speed control (optional)

- High operational safety through efficient lubrication

- Maintenance-free operation

- Mechanical soft-start through pressure compensation while the compressor is starting

SHELL-AND-TUBE HEAT EXCHANGERS

Utilization of durable shell-and-tube heat exchangers as evaporator and condenser for maximum durability and safety of operation

OECC INJECTION TECHNOLOGY - OCHSNER Electronic Cooling Cycle Controller

- Injector for evaporator and economizer

- Highest COP due to precise superheat control

- High operational safety through full compressor protection

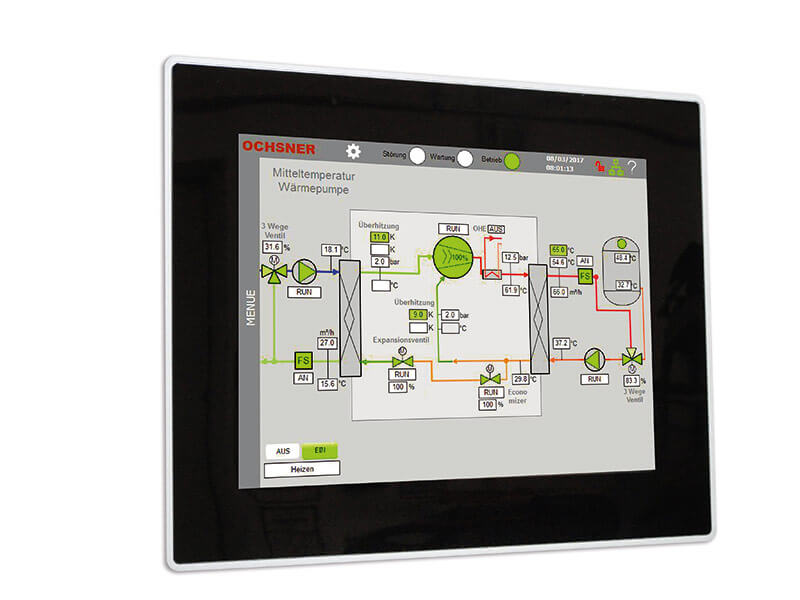

MEGATRONIC MICRO-PROCESSOR CONTROL - 10” Touch Display

- Microprocessor control with 10” touch panel, through which system setpoints are entered and actual values are clearly displayed. The system is visualized using a hydraulic diagram with state display. Popup menus show operating states/data points of system components such as the compressor. All measured values are continuously recorded, monitored, and controlled in real-time. Integrated interfaces for remote maintenance. Any alarms are displayed visually.

- SmartGrid applications for utilizing low tariff periods and heat storage

- Communication-capable controller for easy integration with building management systems for network creation, for example, via MODBUS®.

- Possible continuous remote monitoring and logging of operation status via Internet or LAN. Telecontrol technology enabling Internet access.

- The control was specially developed for high-efficiency compressor operation with economizer in heat pump mode, as well as for two-stage high-temperature cooling cycle.

- Peripheral control enables control of circulation pumps and valves, as well as interconnection of heating, active and passive cooling or buffer management, and much more.

WORKING FLUIDS

Based on years of experience in process applications, OCHSNER has developed high-temperature heat pumps with safe working fluids. This represented a true breakthrough in high-temperature heat pump technology.

Until now, comparable temperatures could only be achieved using CO2 as the working fluid, which however meant limitations on the heat utilization side. OCHSNER's high-temperature working fluid, such as ÖKO1, is non-toxic, non-flammable, and safe. This eliminates the need for complex safety and maintenance measures. Due to the low pressure level and other thermodynamic properties of ÖKO1, complex high-pressure working groups can be avoided, as well as high temperature variations on the heat utilization side. Moreover, ÖKO1 is future-oriented and environmentally friendly due to its low global warming potential (GWP).

As an alternative, OCHSNER offers ÖKO 2 as a working fluid, a safe refrigerant with a GWP value of 1, which meets all ecological requirements of natural refrigerants, and is also non-flammable and non-toxic.

HIGH TEMPERATURE SERIES 82°C - POWER RANGE 30 to 130 kW, cascades up to 390 kW

with screw compressor - fluid temperature 82°C

APPLICATION AREAS

- Heat recovery in hotels, food and pharmaceutical industries, energy supply, data centers

- Hygienically demanding applications of hot water in clinics, nursing homes

- Supporting solution combined with low-temperature heating

- Heat sources: Water or brine

CONSTRUCTION

- Compact space-saving design

- High source temperature between +10°C and +42°C

OUTPUT RANGE

Heating power from 30 kW to 130 kW, cascade up to 390 kW

HIGH TEMPERATURE SERIES IWP 95 - POWER RANGE 60 to 850 kW, TWIN-UNIT up to 1.7 MW

with screw compressor - fluid temperature 95°C

APPLICATION AREAS

- Process technology

- District heating networks

- Heat source: Water or brine from industrial heat or heat recovery

CONSTRUCTION

- Specially designed screw compressors for high temperatures, for heavy continuous operation - Internal circulation cooling system

- Depending on the temperature of the heat source and the radiator, single- or two-stage refrigeration cycle

OUTPUT RANGE

Heating power from 60 kW to 850 kW, as TWIN unit up to 1.7 MW

HIGH TEMPERATURE SERIES IWP 95 - POWER RANGE 60 to 850 kW, TWIN-UNIT up to 1.7 MW

with screw compressor for highest temperatures of 95°C

APPLICATION AREAS

- Process technology

- District heating networks

- Steam generation

- Heat source: Water or brine from industrial heat or heat recovery

CONSTRUCTION

- Specially designed screw compressors for highest temperatures under heavy continuous operation - High-efficiency internal circulation cooling system

- Depending on the temperature of the heat source and the radiator, single- or two-stage refrigeration cycle

OUTPUT RANGE

Heating power from 150 kW to 750 kW, as TWIN unit up to 1.5 MW

TEMPERATURE SERIES 82°C with screw compressors for outdoor air

Heating power 460 kW for L10/W45 and 412 kW for L2/W82

APPLICATION AREAS

- Heating and cooling

- Large-scale buildings, local and neighborhood district heating networks Max. Supply temperature +82 °C

- Supply temperature up to 72 °C even at an outdoor air temperature of -20 °C - Heat source: air

CONSTRUCTION

- Compact design

- Two-stage compressor technology, low GWP refrigerant

- Robust shell-and-tube heat exchanger as condenser

- Fans with variable speed control

OCHSNER INDUSTRIAL HEAT PUMPS - REFERENCE PROJECTS

BLIZZARD SKI MANUFACTURER MITTERSILL

At the Ski Excellence Center Mittersill, the Tecnica Group produces some of the best and top-selling ski models in the world. The heat generated during the pressing process at a temperature of 140°C is efficiently utilized by OCHSNER's high-temperature heat pump.

During the pressing process, each ski is heated to a temperature of 140°C for about 12 minutes and then cooled to a temperature of 20-22°C. The cooling water used for this purpose reaches a temperature of approximately 28°C. Before releasing it to the surface channel, it needs to be further cooled to a temperature of 18°C.

This task is performed by OCHSNER's high-temperature heat pump. At the same time, it utilizes energy to heat a buffer tank with a supply temperature of up to 77°C. The buffer tank provides heating and process heat. As a result, the demand for biomass and district heating in the Ski Excellence Center in Mittersill has significantly decreased.

DISTRICT HOSPITAL IN SCHWAZ

ZASTOSOWANE JEDNOSTKI

- 2 IWWSV 650 ER7A medium-temperature heat pumps with inverter

- 1 IWWHC 60 P2D high-temperature compact heat pump

- 1 IWWHC 30 P2D high-temperature compact heat pump

The District Hospital in Schwaz is the first hospital in Austria that produces heating and domestic hot water solely using heat pumps in regular operation. In the future, fossil energy will only be used to cover peak loads and emergency power supply. In addition to reducing CO2 emissions by 90%, external energy consumption is to be reduced by 50%. For the consistent pursuit of these goals, it received a special award in the "Tyrolean Renovation Award 2021" competition.

The District Hospital in Schwaz, bidding farewell to fossil fuels, aims to implement the energy strategy of Tyrol, says Franz Hauser, chairman of the municipal association. The main role is played by medium- and high-temperature heat pumps from OCHSNER, which largely replace existing gas burners.

The individual energy concept includes two OCHSNER systems for heating and cooling. They use groundwater as a heat source and for passive cooling. Additionally, two high-temperature heat pumps from OCHSNER generate hot water at up to 80°C, ensuring hygienic safety in the hospital area. The flow of heat pumps for heating serves as a heat source here.

IKEA FURNITURE STORE IN INNSBRUCK

IKEA Innsbruck has transitioned its heating (from fossil fuels) supplying sales and warehouse areas to renewable energy. Heating and cooling have been converted to large heat pumps from OCHSNER. The use of heat pumps contributes to the company's goal of making IKEA climate-positive in the coming years.

UNITS APPLIED

- 2 medium-temperature heat pumps IWWS 520 ER2

- 1 unit OWWP 83 plus - heat pump for heating

IKEA Innsbruck is the third store of the Swedish interior design retail chain where heat pumps from OCHSNER Energie Technik have been applied. Further projects are in the planning phase. OCHSNER systems provide heating power of 499 kW twice and cooling power of 385 kW for heating rooms, air curtains at doors, cooling, and hot water supply. In Innsbruck, groundwater is used as the energy source for heat pumps.

Even before the expansion of the sales area, the building relied 100% on electricity from renewable energy sources. A photovoltaic system on large roof areas provides self-generated electricity for the operation of heat pumps as well as for the Tyrolean power grid.

HEAT RECOVERY IN DISTRICT HEATING PLANTS

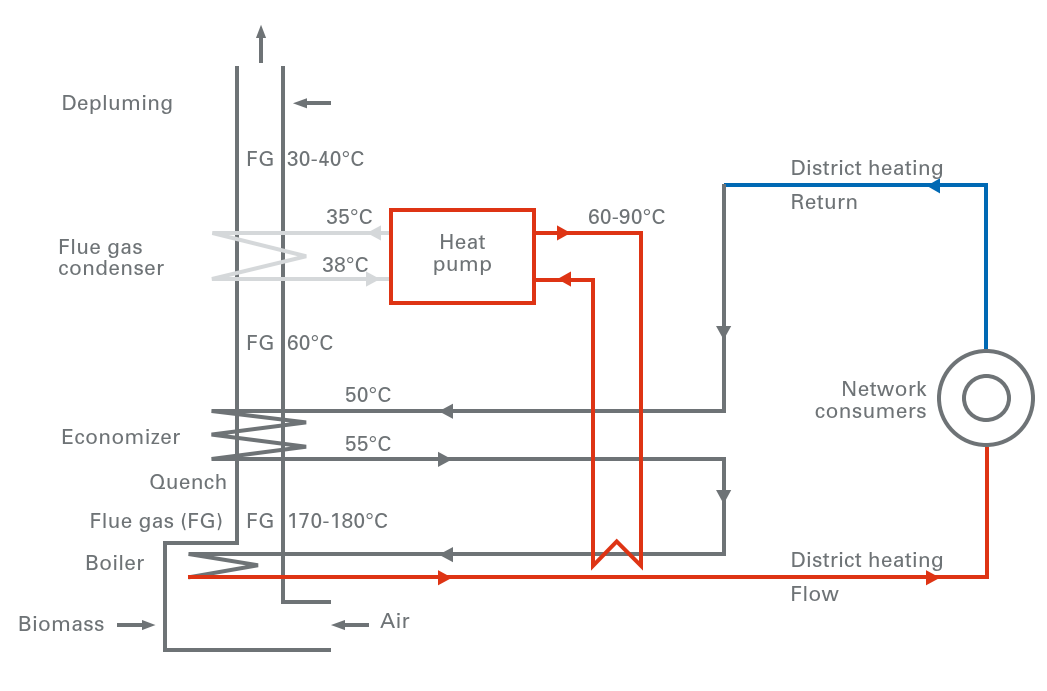

Despite the installation of economizers, unutilized latent heat is typically still present in the flue gases. This heat can be recovered using process heat pumps. Additionally, this process releases additional condensation heat. Increased efficiency and reduced fuel/biomass consumption are the main benefits for the operator.

BIOMASS POWER PLANT IN HALL IN TYROL

The Hall district heating plant generates heat and electricity from biomass. The thermal energy is supplied to Hall AG customers through district heating pipelines and is available for hot water preparation and space heating. By using large heat pumps from OCHSNER, it was possible to increase the heating capacity from 13 MW to 18.5 MW while maintaining the same biomass consumption.

UNITS USED

- 2 IWWSV 985 ER6a medium-temperature heat pumps with frequency converter

- 2 medium-temperature heat pumps IWWS 900 R6a

Simplified diagram of heat recovery from flue gases through high-temperature heat pumps

For some time now, the Hall AG regional power plant has been using flue gases for heat recovery. To increase energy efficiency, Hall AG, together with Haim Technologies GmbH, developed the entire project and process technology. The flue gas installation was equipped with a multi-stage desuperheating and flue gas condensation system.

To increase efficiency, four medium-temperature systems from OCHSNER were used. All heat pumps have frequency control for smooth power regulation, as buffer tanks are not installed.

INDUSTRIAL HEAT PUMPS - reference list

- RESIDENTIAL COMPLEX VIENNA

Source heat well with separate heat exchanger, heating capacity 158kW - IKEA WUPPERTAL

Source heat - geothermal field, heating capacity 2x 270kW and 658kW, cooling capacity 2x 228kW and 557kW - WASTEWATER TREATMENT PLANT IN ANNECY

Source heat wastewater, heating capacity 2x 280kW - MUNICIPAL PLANT IN LÜBECK

Source heat glycol and water mixture, heating capacity 232kW and 66kW, cooling capacity 189kW and 54kW - BIOMASS HEATING PLANTS KRUMPENDORF AND EBENTHAL

Source heat - waste heat from flue gases, heating capacity 245kW and 286kW - NEW HIGH SCHOOL AND SPORTS CENTER SCHWANENSTADT

Source heat waste heat from ice machine, heating capacity 136kW and 180kW - IKEA BERLIN-LICHTENBERG

Source heat sewer channel, misting basin, air conditioning system, supply temperature 40°C, heating capacity 3x 500kW - OLD TOWN HALL BONN

Source heat groundwater, heating capacity 142kW, cooling capacity 157kW - ENERGIE AG

Source heat groundwater, heating capacity 337kW - FRONIUS WELS

Source heat - deep probes, heating capacity 375 and 170kW, cooling capacity 395 and 203kW - CITYGROUP FRANKFURT

Source heat cooling water, heating capacity 2x 175kW - VATTENFALL HAMBURG

Source heat EDP server room, heating capacity 2x 360 kW, cooling capacity 2x 245 kW - ÜBERLANDWERK KRUMBACH

Source heat sewer channel, heating capacity 120kW - PLANSEE REUTTE

Waste heat from processes 45°C, supply temperature 90°C, heating capacity 380 kW, cooling capacity 287kW - MUNICIPAL PLANTS IN AMSTETTEN

Source heat sewer channel, heating capacity 228kW, cooling capacity 185kW - EVANGELICAL PARISH BONN

Source heat groundwater, heating capacity 2x 130kW - VIENNA DISTRICT HEATING

Return temperature from the district heating network 45°C, supply temperature 75°C,

heating capacity 255 kW, cooling capacity 207kW - UNIVERSITY OF BURGUNDY DIJON

Air conditioning system with heat source for servers and offices, supply temperature 90°C, heating capacity 420kW, cooling capacity 255kW - GEMÜ EMMEN

Source heat groundwater, heating capacity 930kW